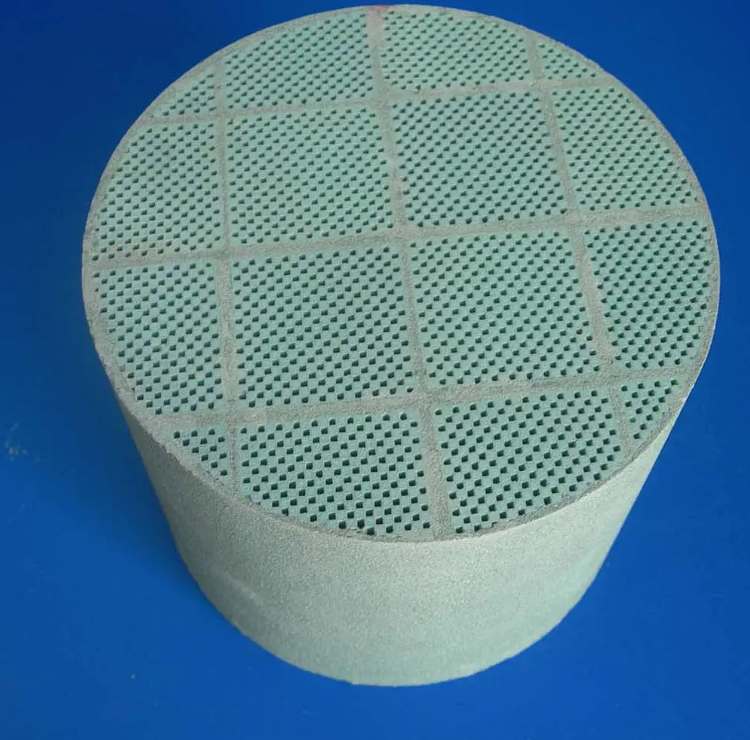

SiC as a special refractory material, has excellent chemical properties. He used in the iron and steel smelting process as blast furnace, cupola, such as stamping, corrosion, wear serious parts of refractory lining material; in the non-ferrous metal (zinc, aluminum, copper) smelting project as smelting furnace lining, molten metal conveying pipeline, silicon carbide foam filter, crucible, etc.; in space technology used as rocket engine tail nozzle, elevated temperature gas turbine blade; in the silicate industry, a large number of used as a variety of furnace boards, muffle furnace lining, saggar; in the chemical industry, used as gasoline generator, petroleum carburetor, desulfurization furnace lining.

When SiC composite with different refractories, and can make numerous types of composite refractories, and has a wide range of uses. In monolithic refractories, the monolithic refractories containing SiC of elevated thermal conductivity, tiny linear expansion coefficient, and elevated wear resistance and nearly different blast furnace slag and other characteristics such as low basicity slag reaction, thus, containing SiC monolithic refractories have been widely used in steel industry, garbage incinerator, the cement industry, thermal power plants and other industrial areas, with other amorphous refractory irreplaceable superior performance.